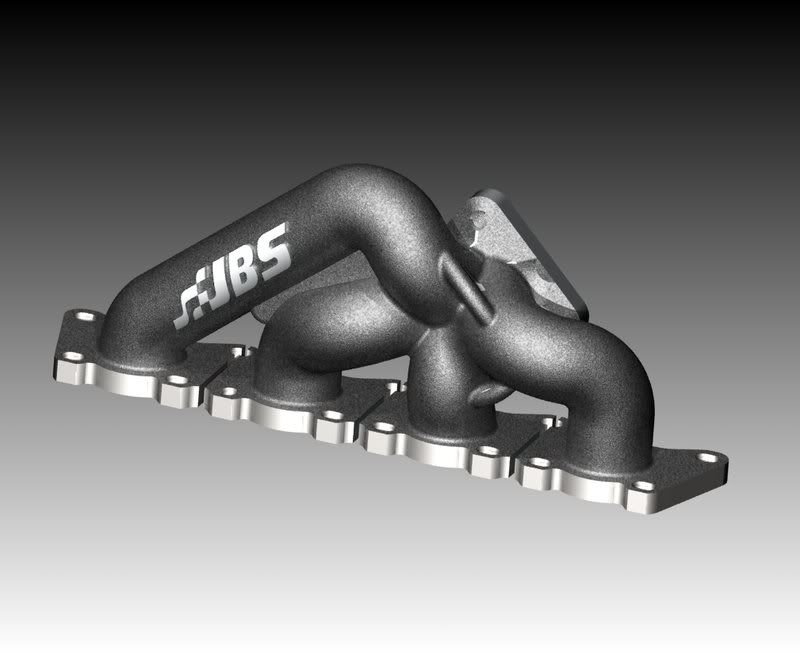

The JBS development team has been working on a new cast K03 performance manifold, alongside this we have been working on a new GT28, Twin Scroll and the IHI stage one manifolds, which are also to be cast and will run alongside the new JBS tubular designs.

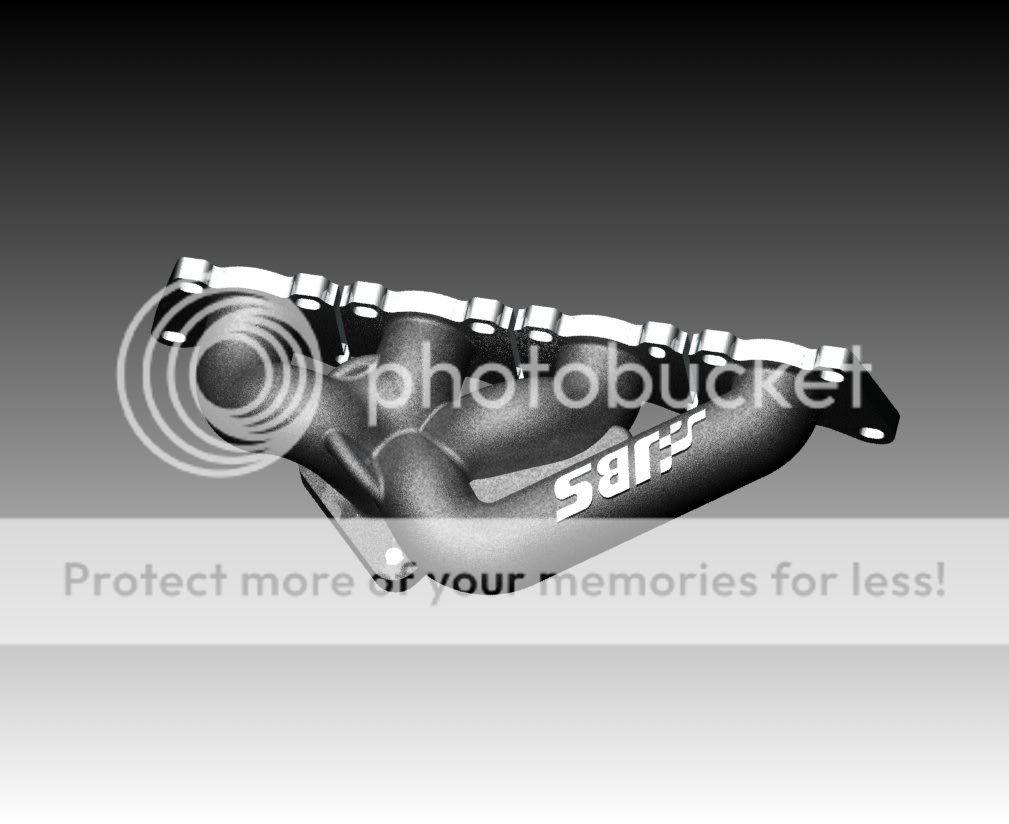

JBS will produce the tubular manifold, but due to a drop in manufacturing quality the new IHI tubular design will be produced in house. The new designs concentrate more on collector efficiency and eliminating port sharing.

Once the process of designing a cast K03 manifold started it became a lot easier to produce cast manifolds to suit other turbos. Having the new manifolds cast gives better quality to mass production and gives fewer constraints on the pipe bend radiuses, collector design and also allowing the runners to flow freely. Making the new JBS designs far superior to the competition.

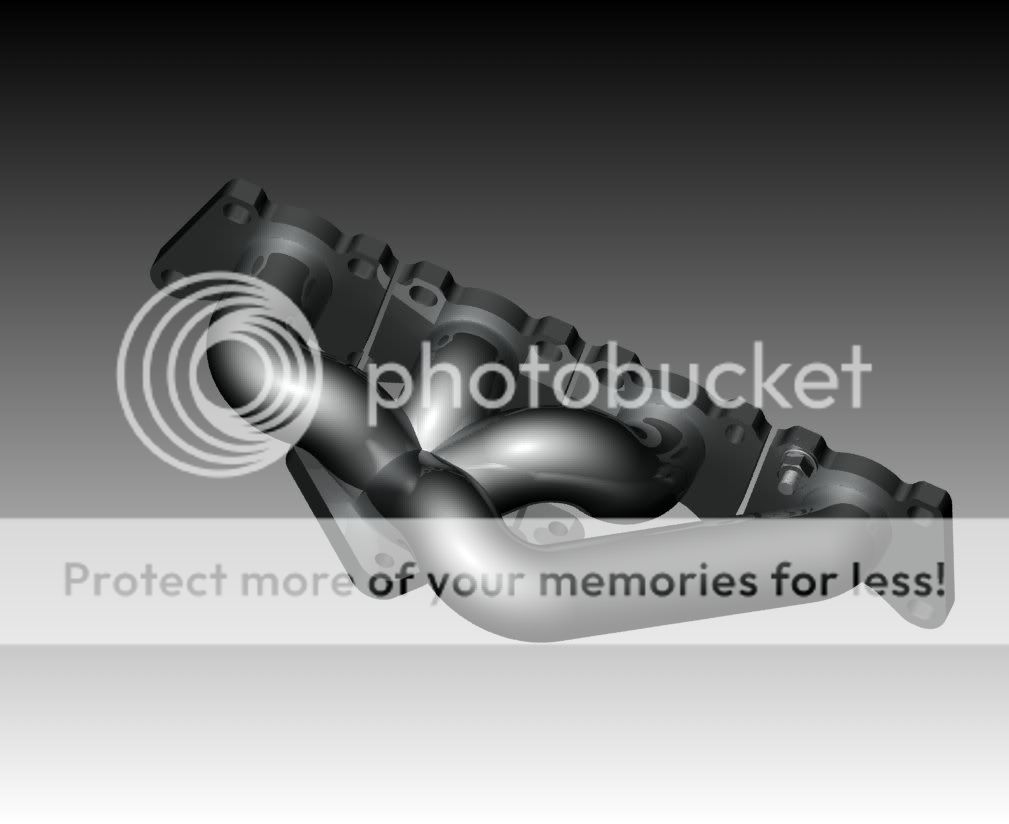

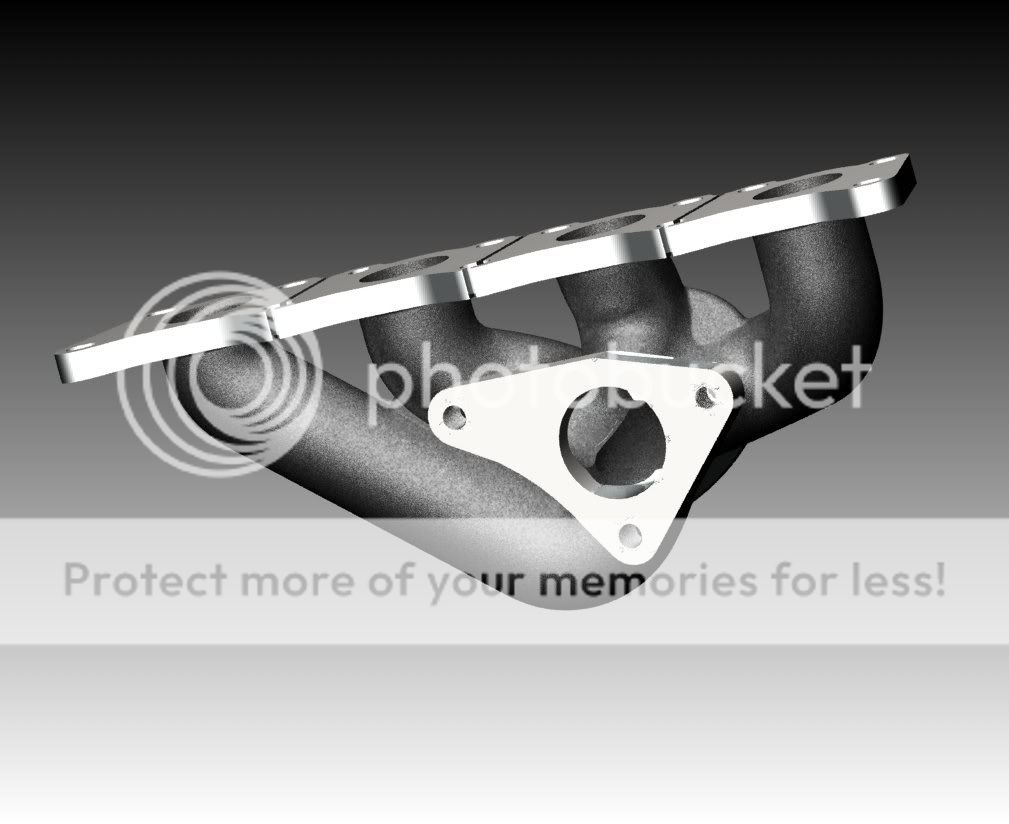

The manifold has been designed in CAD to optimise the collector, flow capabilities and to enable easier fitment. The CAD process allows the designers at JBS to manipulate the part quickly and while allowing information and measurements to be taken easily, which would be physically impossible to do by hand.

The new JBS manifold design runs through the range of new cast and tubular manifolds, with the runners and collector being specially designed for the casting process to give the greatest flow.

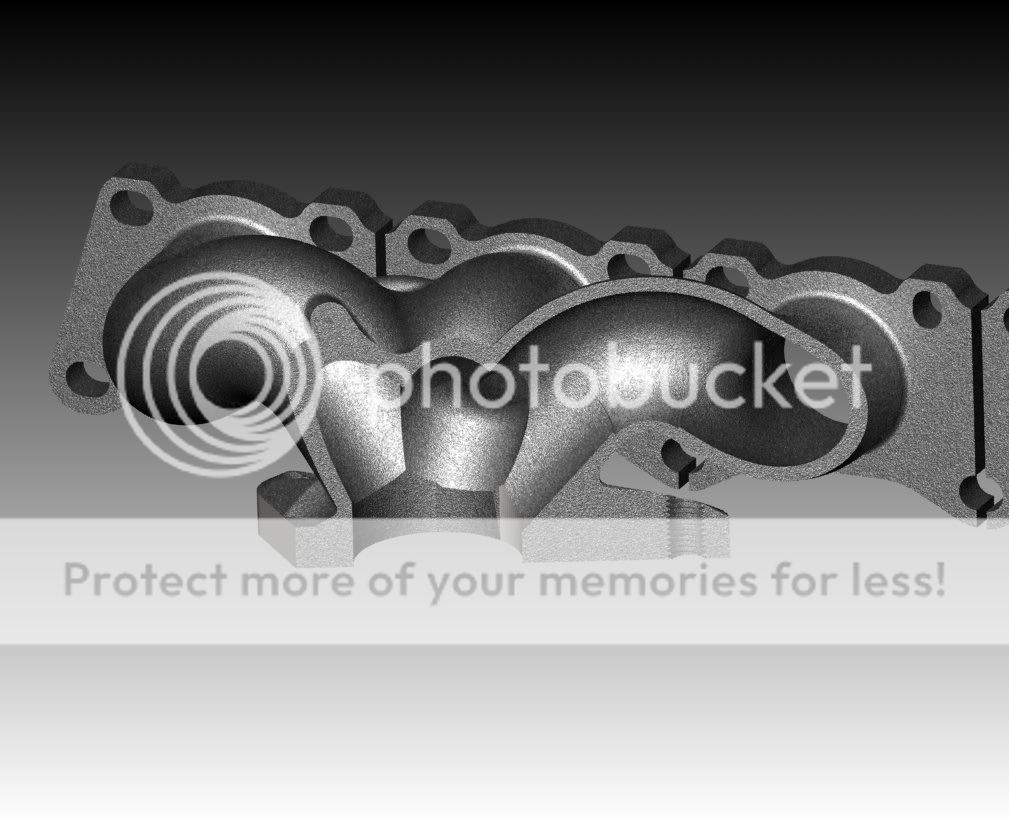

The new design flows the combustion gasses through a close to 90 degree angle in the runner before they enter the collector. Changing the direction of the flow in such a way gives better directional flow of the gas into the turbine, as well as defeating port sharing. Port sharing occurs on many of the flat manifold designs produced by other companies.

The cylinder head flange has been redesigned to allow greater thermal expansion and movement between the runners. The designers found that a too restrictive flange forced stresses back through the runners of the manifold which lead to crack propagation.

Once we were happy with our design it was sent off for rapid prototyping to give us a physical model to evaluate before any design finalisation can take place. The rapid prototype is a highly accurate model taken straight from the CAD data.

JBS has chosen to cast its manifolds in a very high quality UK based foundry which is used by the likes of Borg Warner and many other OEM turbo suppliers to ensure the castings are of the highest quality. To reflect the high quality casting, we have chosen the same material as the hot side of the turbochargers D5S ni-Resist is a cast irons with high nickel content has the following properties: resistance to corrosion, resistance to oxidisation and high temperatures, resistance to wear and erosion. This is to ensure a minimal amount of thermal expansion and an equal rate of thermal expansion to the turbo housing, this again minimises the potential for thermal fatigue.

Once the first batch of manifolds are produced, they shall be thoroughly tested and dynode. At which time all power and flow figures will be released. Once all testing is completed and we are happy with the results we aim to release the manifolds at £420 including VAT.

We also have a K03 cast manifold going into production with the new IHI and GT28 stage one manifolds. As well as having K04 and Twin Scroll manifolds going through our design process and rigorous testing and hope to be able to bring them to you as soon as possible.