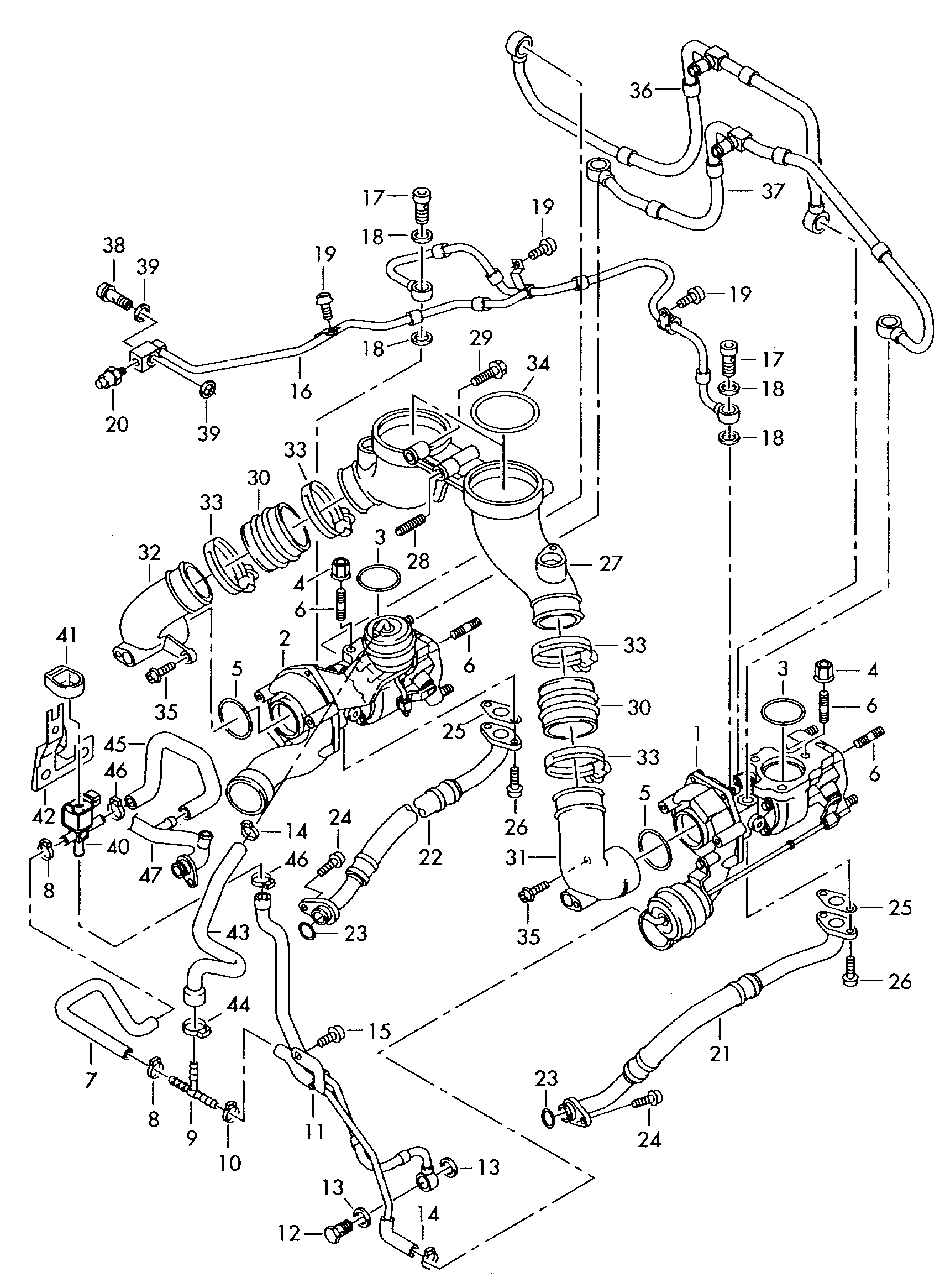

Some confusion here. Number 36 are the DVs. They're not dump valves on the RS6, they are diverter valves because the charge pressure is not lost to atmosphere but recycled (since the air has been metered).

The wastegates are actually part of the turbo and are valves to let the exhaust gas bypass the turbine to prevent the compressor wheel spinning up (and causing boost).

The waste gates operate in one of 2 ways:

1. The pressure builds up to a point where the spring holding the wastegate closed is overcome and (some of) the exhaust bypasses the turbine wheel. This way the turbo can't spin too fast (bad).

2. The wastegate has a external actuator which is operated by pressure from the compressor side of the turbo (via the N75). When the pressure is sufficient, this causes the wastegate to open, causing exhaust gas to bypass the turbine. The N75 controls this compressed air flow to regulate the turbo.

The wastegate's function is to allow limiting rotational speed of the turbine to safe levels (for longevity) and to allow regulation of the boost.

The diverter valve has no regulating effect on the turbo. When you lift of during boost, the compressed air needs to go somewhere. It can't go into the engine because the throttle plate has closed, so it needs to be diverted back to the intake pre-compressor so that is can continue to circulate. If you didn't have a DV then the back pressure from the air being able to go nowhere would slow the turbine right down. This means that when you require boost again, you need to do all that work to get it up to speed to compress the inlet air again. [A blow-off valve is a crude device that opens and lets this excess pressure vent to atmosphere. RS6s don't have em. No production cars do, I suspect. Probably lots of Subarus have them fitted, judging by the silly noises they make.]

So... when you said you changed the wastegates previously, did you mean you changed the DVs?