I'd always wanted to change the wheels, but could never find something I was totally happy with until now and was going to be close enough to OEM, but still OEM+++++++. I'd always had a bit of a phobic reaction to most aftermarket wheels I saw so this was always going to be a really tough, drawn-out decision and very specific design for me to be happy.

Re OEM - I'd always loved the rotors - classic, but a little overused by Audi these days. Recently I had been tempted by the V-spokes - very nice looking. Between these two I abstracted the design cues and came up with the following:

- 5 points of symmetry look best to me (rotors and V-spokes both have this)

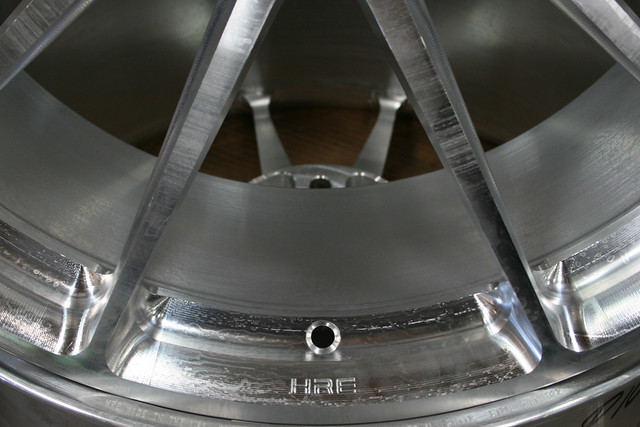

- Open design of the V-spokes to show off the brakes

- Concave as I could

- Colour to blend with the dark chrome I've done recently

- 21" to show off the brake setup

- Option to customize (more to follow on that one later)

- Michelin PSS tyres - I desperately wanted to keep the option for these as I love the tyre for many reasons including the kerb protection

This narrowed down the search and with the help of a few people (you know who you are [;)] ) then I got down to a shortlist. Then I spotted the P104 from HRE and knew these were the ones.

HRE Wheels wrote:HRE’s Street Collection combines the technical expertise from our championship-winning racing wheels with an uncompromised attention to detail creating the ultimate in lightweight, high-strength performance forged wheels. This race-bred philosophy ensures enhanced braking, acceleration and handling while also reflecting your distinguished sense of style. Each model in HRE’s Street Collection of custom wheels is designed specifically for supercars, sports GTs and performance sedans.

http://www.hrewheels.com/wheels/series-p1/p104

Specifications

http://www.hrewheels.com/wheels/series-p1/p104

Specifications

- Monoblok 1-Piece

- Modern Conical profile creating the strongest, lightest P Series yet.

- Aerospace-grade 6061-T6 forged aluminum for high strength-to-weight ratio

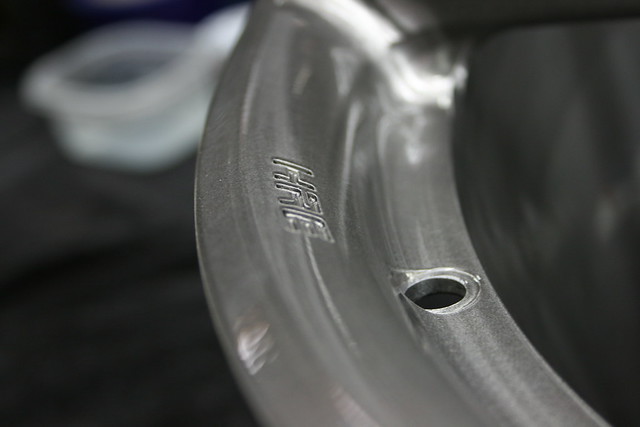

- Side Cuts and backpad pocketing are standard to minimize unsprung mass and rotational inertia for maximum performance and handling

- CNC machined to custom specifications for your specific application

- OE TPMS and lug hardware compatible for ease of installation

A big BIG thank you to the guys at HRE (you know who you are) for taking the time to take all these wonderful photos of my wheels in production. I am no expert, so as much as I'd like to do a detailed write-up and sound really knowledgeable I can't, but again the guys at HRE have supplied some notes I have posted along with the photos.

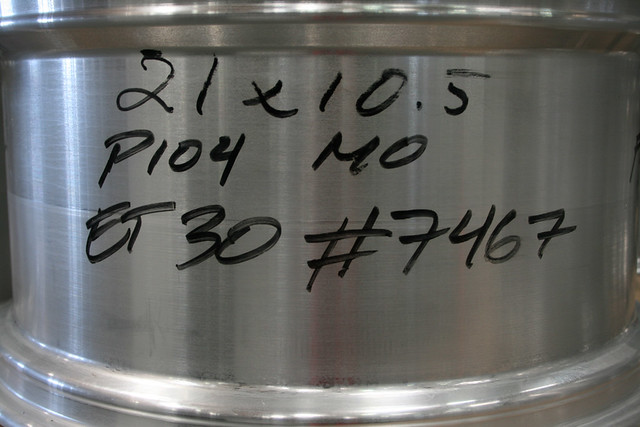

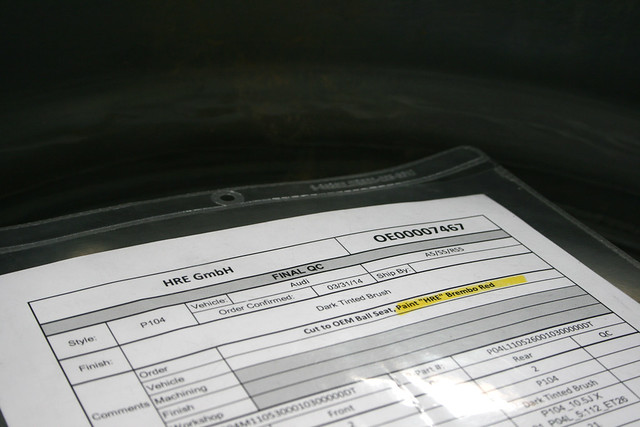

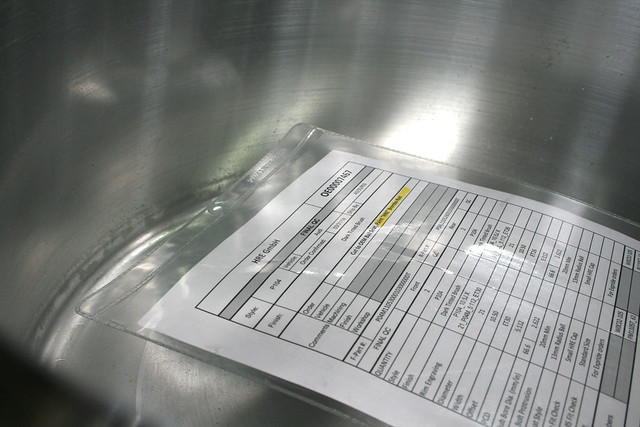

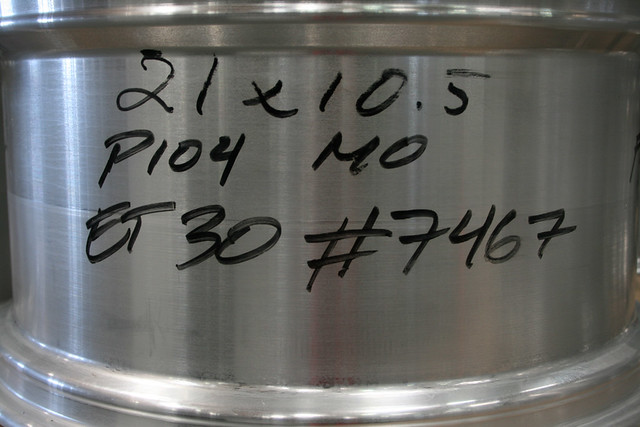

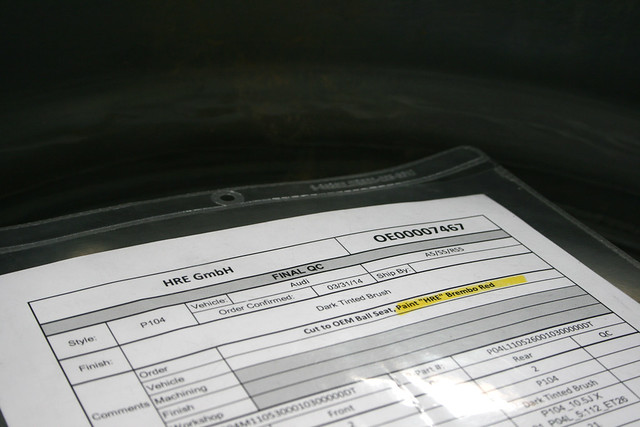

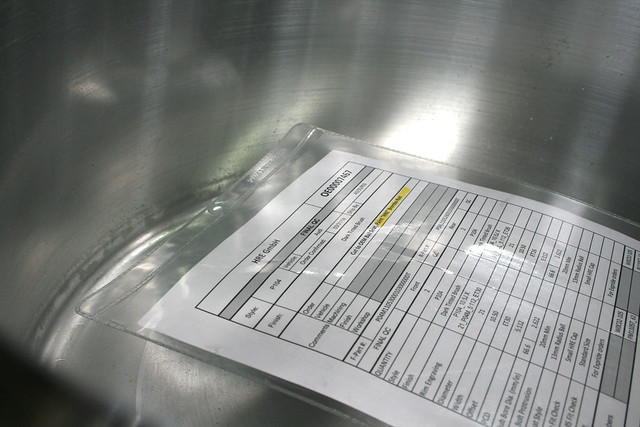

Stage 1: Forging staged for production with an assigned traveler. Each customer order goes with and stays with the forgings on their journey. All information (width, offset, finish, etc.) is on this sheet can be referenced at any point during the journey.

Stage 2:

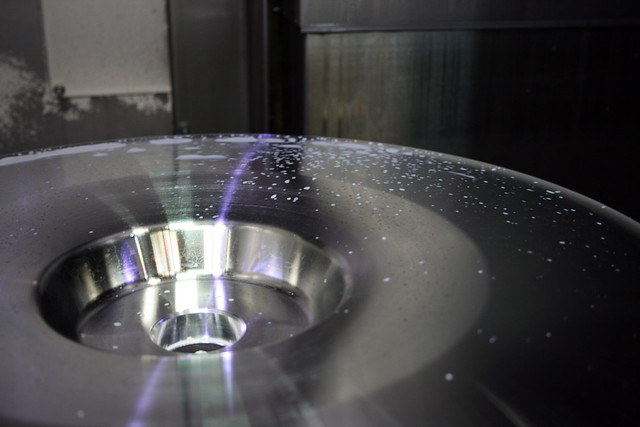

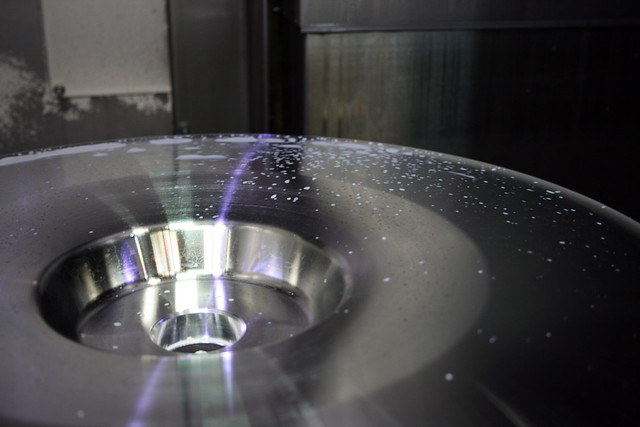

Stage 2: All four wheel forgings at the lathe, being machined. This is where the face of the wheel is refined. It’s at this stage that the center bowl takes shape.

Stage 3:

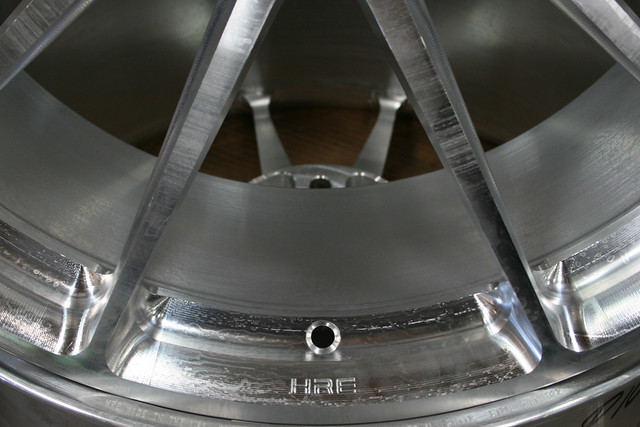

Stage 3: From the lathe, the wheels are then sent through milling. At this stage, the wheel “windows” and spokes are sculpted and carved out, using a variety of tools – each wheel takes about 2 hours (roughly) to complete at this stage. The Series P1 involves a milling process called “kellering” which allows curved and sculpted milling to take place vs straight ball cutting which is utilized on the Series P40SC. This process adds a considerable time to the milling.